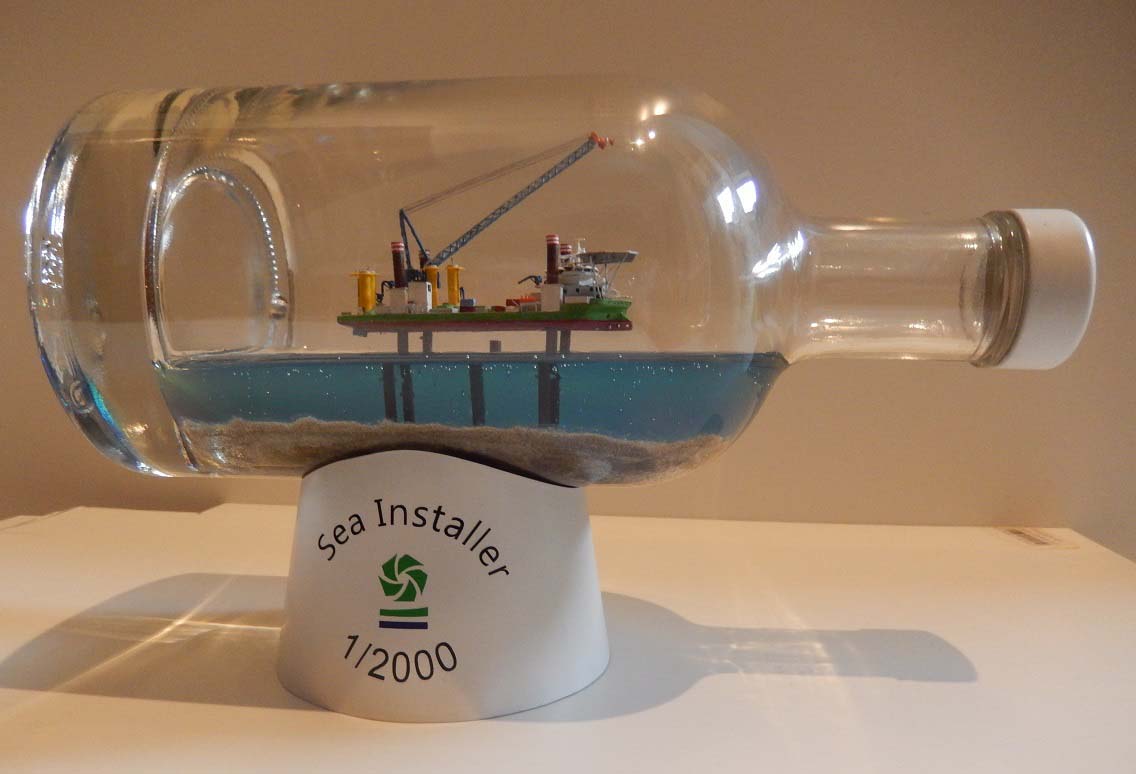

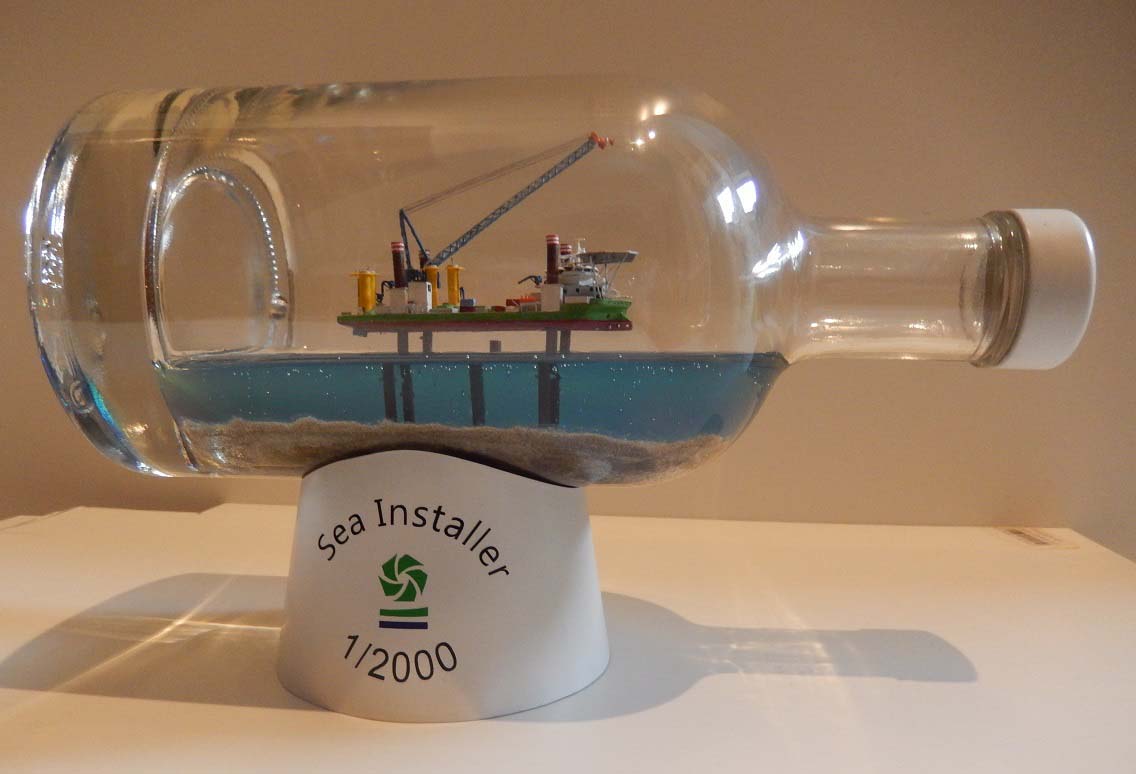

1/2000 Sea Installer (scratch built)

|

by Roel Van de Velde |

1/2000 Sea Installer (scratch built)

Sea Installer:

This is my model of Sea Installer. The scale is 1/2000 and she is fully scratch built.

I always wanted to build a ship in a bottle, but considering my focus on merchant ships, I never really found ships that would fit a bottle at a decent scale. Either they were too long and slender and would fit as 1 piece through the bottle neck if the length were to match the bottle length, or they would be so flat that the height of the bottle would hardly be filled at all.

When looking at these Wind Installation Vessels, it dawned on me that they’d be a good subject for this purpose.

Far from regular and old fashioned ships in bottles, it required a lot of engineering to enable me to put this ship in the bottle. Of course I gleaned a lot of tricks from more experienced ship-in-bottle (SIB) builders, applying those with a little twist to fit my purpose.

The original vessel was built along with the Sea Challenger as jack-up offshore wind installation vessels for the Danish company A2Sea, they were later on bought by the dredging and marine engineering company DEME from Belgium.

They are used to install monopile foundations on the seabed, transition pieces between the monopiles and windmills and the windmills themselves. For that they are equipped with a leg revolving heavy lift crane. When the legs are up, they can navigate to collect pieces and transfer them to the offshore wind field, for that they are equipped with a rather odd 3-piece Voight-Schneider propulsion.

The model itself shows a monopile on the bottom of the sea, the Sea Installer in position preparing to install a transition piece (yellow mushrooms on its deck) on the monopile.

Choosing this time frame allowed me to erect the crane slightly, in order to fill up the height of the bottle properly. In normal cases, during installation the crane would be fully topped up, but that wouldn’t fit inside the bottle.

The bottom is filled with sand, mixed with acrylic gel to fix it in place, while the sea is made from epoxy. It appears there is some reaction between the two as at the end of the epoxy curing process some bubbles are formed, they can not really escape anymore since the viscosity of the epoxy is already too high at that time. I did this process a second time, covering the sand with a layer of pure acrylic to embed any remaining air between the sand beads, but the final result was the same. I’m therefore assuming it is some kind of reaction between the acrylic and the epoxy that causes those bubbles.

I also etched the company logo on the outside of the bottle in the back, to fill up that empty space a bit. It can hardly be seen through the bottle, but it came out ok. It was etched on the backside, with the bottle normally pointing to the right. I had the feeling it would draw too much attention when etched on the front.

The support represents the top of a wind mill, with the bottle acting as the body. I planned to put a hub around the bottle neck and cap, but the model of that hub was so big that it took too much attention away from the model itself. I therefore decided to just paint the bottle cap white.The full construction was documented in the modelwarships forum.